/Coils/Hot Dip Galvanized Coils

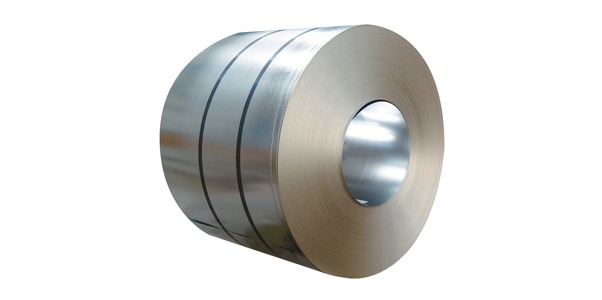

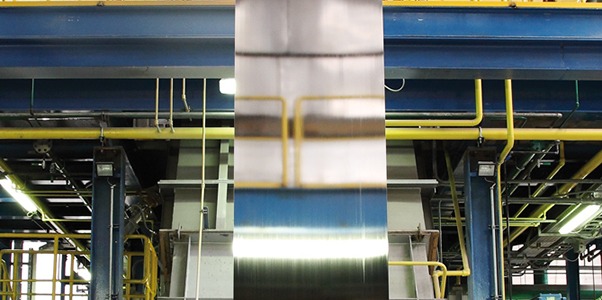

HOT DIP GALVANIZED COILS

Marcegaglia Poland offers a wide range of hot dip galvanized coils in compliance with EN 10346 Steel flat products for cold forming, Structural steels, High yield strength steels for cold forming, Dual phase steels, ASTM A653 Hot dip zinc-coated steel.

In addition, Marcegaglia can offer a range of structural steels for construction according to Marcegaglia standards.

| PRODUCT RANGE |

||||

| Thickness (mm) | Width (mm) | |||

| 1000 | 1250 | 1500 | 1530 | |

| 0.25 ÷ 0.29 | • | • | ||

| 0.30 ÷ 0.34 | • | • | ||

| 0.35 ÷ 0.39 | • | • | ||

| 0.40 ÷ 0.49 | • | • | • | |

| 0.50 ÷ 0.59 | • | • | • | • |

| 0.60 ÷ 0.69 | • | • | • | • |

| 0.70 ÷ 0.79 | • | • | • | • |

| 0.80 ÷ 0.89 | • | • | • | • |

| 0.90 ÷ 0.99 | • | • | • | • |

| 1.00 ÷ 1.19 | • | • | • | • |

| 1.20 ÷ 1.29 | • | • | • | • |

| 1.30 ÷ 1.39 | • | • | • | • |

| 1.40 ÷ 1.49 | • | • | • | • |

| 1.50 ÷ 1.69 | • | • | • | • |

| 1.70 ÷ 2.10 | • | • | • | • |

| 2.11 ÷ 2.39 | • | • | • | • |

| 2.40 ÷ 2.50 | • | • | • | • |

| 2.51 ÷ 3.00 | • | • | • | • |

MANUFACTURING STANDARD | PRODUCT DESIGNATION

| EN 10346 | Steel flat products for cold forming |

| EN 10346 | Structural steels |

| Marcegaglia standardSTP 0074 | Structural steels for construction |

| EN 10346 | High yield strength steels for cold forming |

| EN 10346 | Dual phase steels |

| ASTM A653 | Hot dip zinc-coated steel |

| Upon request: supply of grades not included in the above mentioned standards or grades according to customers’ standards, including major automotive manufacturers. | |

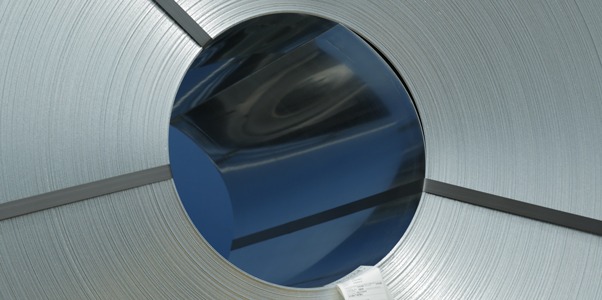

TECHNICAL CHARACTERISTICS

| Coating | Coating is expressed in weight of zinc (g) over one square meter of product (total of two sides) |

| Surface finishes | Standard finish for industrial useSkinpassed surfaceSmooth cylinder skinpassDouble smooth cylinder skinpassHighest standard of finish |

| Surface appearances | Normal spangle Reduced spangle |

| Surface treatments | Surface protection from oxidation, with improved suitability for plastic deformation.Chromate conversion coating resulting in the formation of a passivating film. Only trivalent chromium is employed.Transparent or semi-transparent organic coating with special protective, lubricant and antifingerprint properties. Available for thicknesses up to 1.4 mm. |

| SUPPLY CONDITIONS |

|