HEAVY PLATES

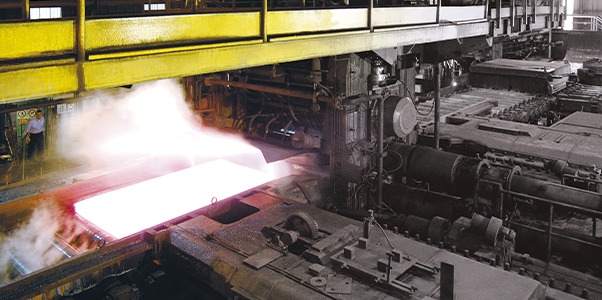

Marcegaglia’s range of heavy plates is manufactured in the dedicated Marcegaglia Plates plants located in San Giorgio di Nogaro (Udine), in the north-eastern part of Italy, with a total production capacity of approximately 1 million tonnes per year.

The production of quarto plates also includes heat treatment, allowing the achievement of an extremely wide range of steel grades and manufacturing standards, making Marcegaglia Plates suitable for the most demanding application sectors.

Structural steels – Applications

- Bridges

- Yellow goods

- Railway infrastructure (DBS)

- Public infrastructure sector (NF Aciers)

- Wind mills

- Road plates

- High-yield grades

- Laser-cut grades

PVQ steels

- Steels for boilers and pressure vessels with temperature-specific characteristics

- Fine-grain weldable steels for normalized pressure vessels

- Steels for quenching, case-hardening and tooling

- Non-alloy quenched steels

- Alloy quenched steels

- Case-hardening steels

- Steels for naval purposes (work in progress)

- Steels for naval applications according to ASTM and RINA standards

| PRODUCT RANGE | |

| Min-Max. thickness (mm) | 7* – 250 ** |

| Min-Max. width (mm) | 1,000 – 3,020 / 3,000*** |

| Min-Max. length (mm) | 2000 – 21,000 |

| Max. plate weight (kg) | 24,000 |

* Subject to mill approval

** CE marking extension up to 200 mm

*** Raw edges / trimmed edges

| SUPPLY CONDITIONS |

|

MANUFACTURING STANDARD - PRODUCT DESIGNATION

| EN 10025-2 | Non-alloy structural steels (*) |

| EN 10025-3 | Normalized/normalized rolled weldable fine grain structural steels (*) |

| EN 10025-5 | Structural steels with improved atmospheric corrosion resistance (*) |

| EN 10028-2 | Boilers and pressure vessels steel with specified elevated temperature properties |

| EN 10028-3 | Weldable fine grain steels normalized, for boilers and pressure purposes |

| EN 10083-2 | Steels for quenching and tempering |

| EN 10084 | Case hardening steel |

| ASTM | Carbon steel plates of structural quality for general application |

| ASTM | Pressure vessel steel plates |

| ASTM | High-strength low-alloy NbV structural steel |

| API 5L | Steel plates for elbows and fittings |

| RINA | Steel for naval construction |

| RINA | High yield strength steel for naval construction |

| (*) CE marking available | |

TECHNICAL CHARACTERISTICS

| Supply condition |

|

| Standard testing |

|

SERVICE CENTER

- 1 heat treatment furnace

- 1 edge machining (C45 quality)

- 1 shot blasting machine

- 1 cold levelling

- 5 oxygen cut-to-length and trimming

|

Product marking allows the complete identification of heavy plates |

|